Once safely out of the water, it was time to start on some of the other jobs.

Firstly, we needed to take the opportunity to check out the underside of the boat: condition of the copper coat, keel, rudder, propeller and anodes.

We noticed that, in some places, the coppercoat was a little flaky. Also, the weed growth had gone above the copper coat and was stuck fast to the gel coat. This is because we are carrying extra things on board and Escapade is sitting lower in the water than she was. Discussing this with the staff at Fox’s, we agreed that we wanted the copper coat extending higher. Unfortunately, it is too cold at the moment to apply the coating effectively, so we will need to come out at a later date to have the work done.

Checking the propellor and rudder shoe, both needed a good clean and repaint. Also the anodes needed replacing. As we were coming out again in a few weeks, we decided to leave this job till next time. The later we leave these jobs, before we go, the longer we will have before they need doing again!

One of the main reasons for Escapade to come out was to replace the sonar heads.

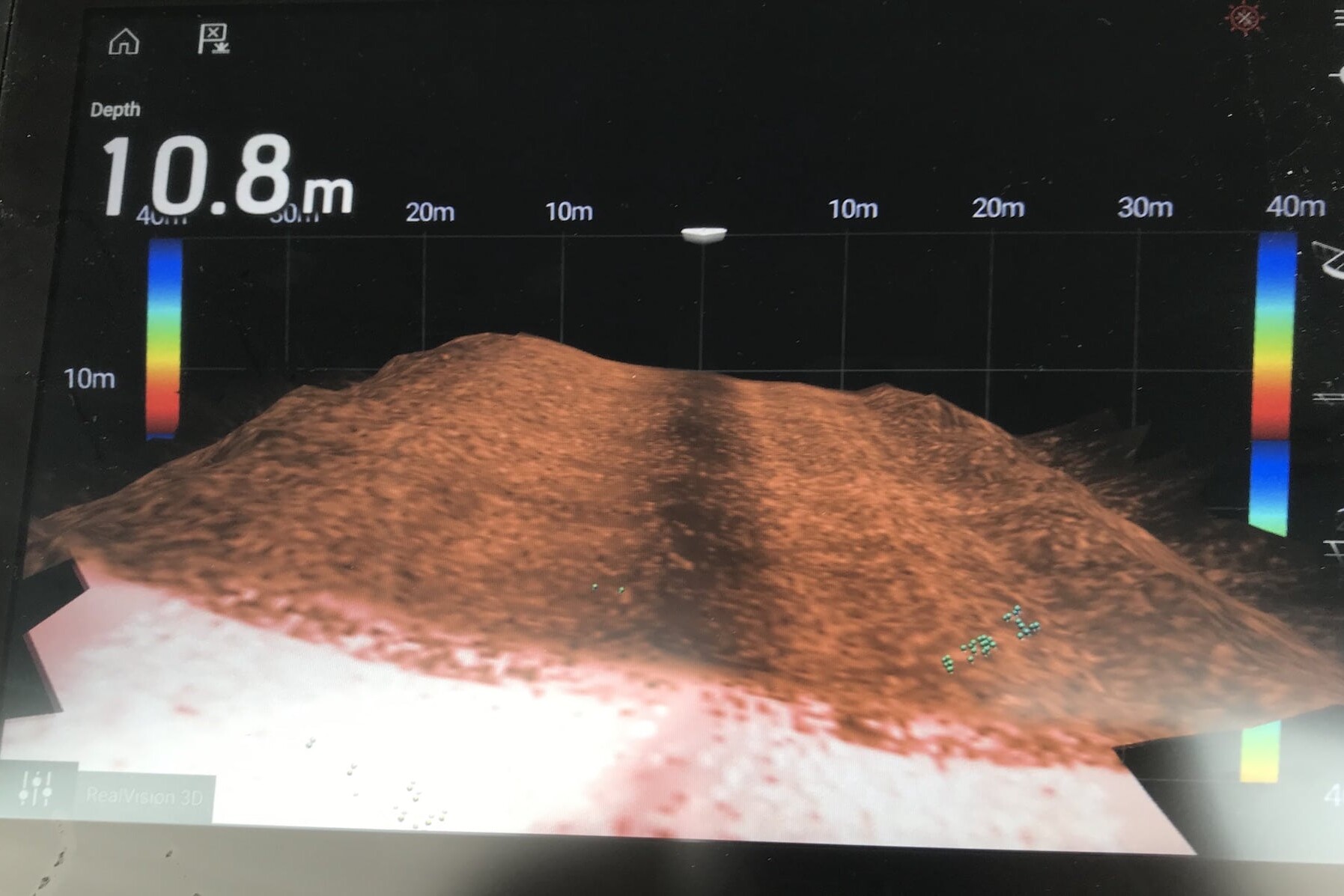

Sonar will give us a picture of the sea bed below us and is really useful when choosing anchoring spots or navigating in unknown places. Unfortunately, although our new heads were giving us a very clear picture of the sea bed, they seemed to show a slope to the right – no matter where we were. After much discussion and online testing with Raymarine, it was decided that there was a fault with them and they needed replacing. A job for Fox’s Boatyard.

The hardest part was removing the old ones, which were well fixed in with sikaflex (a kind of marine grade version of silicone). Perseverance and a large hammer and they were out. A quick clean up and new ones fitted. Lovely job, thanks Nigel!

Next we will need to get back out on the water to test them – fingers crossed they work now.

While I was cleaning and Fox’s were replacing the sonar heads, Martin was also working hard. He was preparing to attach the chainplates to the back of the boat for our storm drogue. As with any of Martin’s job, the bulk of the time was taken up with planning and preparation – nobody like to drill holes in the wrong place. Also, as with most boat jobs, access was not easy and Martin spent most of the week inside the rear lazerette with his arms bent up behind the gas locker! Eventually, the boat and plates were ready to drill. Next job is to fit them.